- Home

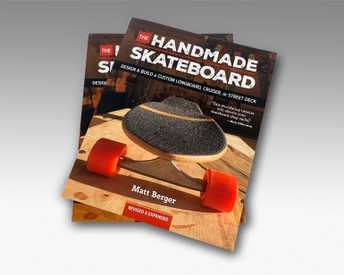

- Skateboard Building

- Longboard Birch Veneer Sets

Longboard Birch Veneer Sets

Product Description:

If you have ever seen a birch tree swaying in the wind, you know that birch will bend a long way without breaking. Use birch instead of bamboo to add flex to your boards. Birch is also slightly lighter than either bamboo or maple.

Please note that this is solid birch. It is not formed with layers of plywood as Baltic Birch is. Using this birch veneer will allow for more radical bends than Baltic Birch and will make a very strong board.

Longboard Birch Veneer

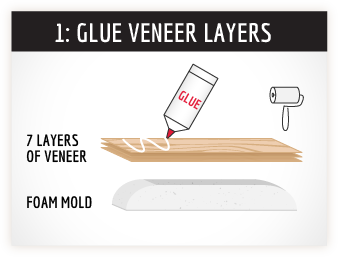

- 7-Layer Set: 2 Face, 2 Cross band and 3 Core sheets

- 8-Layer Set: 2 Face, 2 Cross band and 4 Core sheets

- 9-Layer Set: 2 Face, 2 Cross band and 5 Core sheets

- 12 x 47 x 1/16”

Glue (estimated) per board: 18 oz (7-layer), 19 oz (8-layer), 21 oz (9-layer)

We offer birch veneer as an alternative and/or addition to our maple skateboard veneer. As with the maple, this is rotary cut to 1/16” thick.

Builders have been mixing birch with maple to build a hybrid board that combines the strength of maple with the flexibility and lightness of birch.

Our solid birch veneer is not to be confused with Baltic Birch which is already a plywood, made from layers of birch with a cross ply in the middle. Solid birch veneer will allow you to achieve much more radical shapes than the plywood.

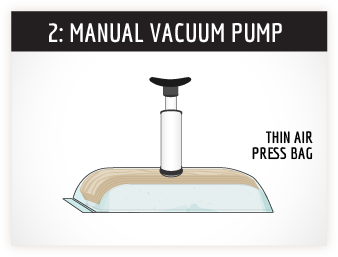

Design and build your own custom longboard using this premium 1/16” thick veneer. This veneer is best used in a Thin Air Press vacuum bag, which applies pressure evenly over the entire board. It eliminates the problem of voids and missed spots, a common problem with some other types of presses.

Using many layers of 1/16” veneer will allow you to create fairly radical curves, which will add strength to your board.

Consider the amount of flex you want to build into your new board. Experiment with using 7, 8, 9 or even more layers of veneer.

When laying up your board, follow the rule that your cross grain sheets should always be layered closest to the middle of your stack, with one layer of core in between the 2 cross grains. We do not recommend any more than 2 cross grain sheets per board.

As this is a relatively new material for skateboard building, have a read through this information and let us know what you think!

Veneer expands and contracts with moisture. Our veneer is shipped with 7-9% humidity. Keep your veneer stored away from heat sources, and lay it flat.

If your work area is very dry, keep your unused veneer sealed in plastic (a garbage will do) until you are ready to use it.

Until it is laminated together, veneer sheets are prone to splits, especially the cross grain sheets. Handle them with care, but if any sheets do split, they can be repaired with a bead of glue and masking tape.

Q: What species is this birch?

A: Betula Alleghaniensis is the name. It can be yellow or white birch, all harvested in North Eastern Canada. The color refers to the bark mainly, as inside the wood is the same color for both yellow and white birch.

Q: How long can I store unused veneer for?

A: Very important to store it laying flat and away from any heat sources. Veneer will absorb and release moisture all the time, so seal the veneer in plastic if the environment is changeable.

Q: What if my veneer splits?

A: Run a bead of glue along the split edges. Use masking tape strips to tightly squeeze the edges together and wait about 2 hours for the glue to dry. Remove the tape before using it.

Q: What is the different between the Face, Core and Cross Band sheets?

A: Face sheets are sorted as the clearest layers for the top and bottom of your board. Core sheets are the internal layers, and will have imperfections such as small knots and holes, splits, sap lines and other color variations. Cross grain sheets (also refered to as xbands, or cross bands) have the grain running in the 90˚ direction to the other long grain layers.

Q: Why do I need cross grain sheets at all?

A: The 2 cross grain sheets spread out the torsional resistance. When riding a board and you lean your weight on the outside edge, the cross grain layers will make the entire board flex, rather than only the edge you have pressure on. Xbands also stop the board from potentially splitting along the length of the long grain.

Q: Is this Birch harvested from sustainable sources?

A: The mill we source our maple and birch from complies to and is certified by the Sustainable Forestry Initiative® Program, a worldwide recognized service.

Loading... Please wait...

Loading... Please wait...

USA

USA

Calculated at checkout

Calculated at checkout