- Home

- Woodworking

- Veneer

- Woodworker Veneer Pack

Woodworker Veneer Pack

Product Description:

The 1/16” thickness is ideal to use when you are creating a structural object such as a furniture part or drawer front. You can quickly build up thickness without using as many layers of thinner, more expensive veneer. The grains are very attractive, and can be left with maple as the finished layer.

These sheets are 12 x 47 x 1/16” with the grain running in the long direction.

Woodworker Veneer Pack

- each pack includes all long grain, Face grade, rotary cut stock

- sheet size is 12 x 47 x 1/16”

- you can specify either maple or birch, or a mix of both

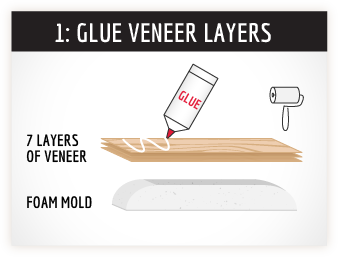

The 1/16” thickness allows for either flat-sheet or bent-wood laminating.

This thickness is ideal for vacuum pressing multiple sheets and gives your project structure and strength. Curved drawer fronts are an example of how the veneer itself becomes the structure. With the addition of a fancy veneer, it makes a complete, easy but awesome looking bending.

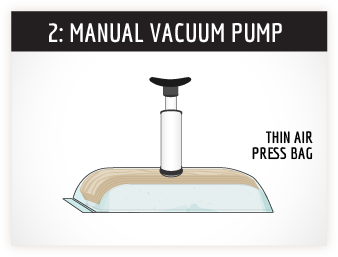

Specially suited for vacuum pressing with water-based glue, maple and birch laminate well in the Thin Air Press Kit.

We also carry stock of color-infused dyed sheets to create a colorful edge profile or include as part of a marquetry pattern. Or, instead of applying stain, use colored veneer as the top sheet. With a light sanding and clear top coat, the grain patterns show through the dye beautifully.

Best Vacuum Bag size: 36 x 52” Thin Air Press TPK36

OR the: 20 x 70” Thin Air Press TPK20

As noted in the details area, any splits or cracks due to handling can be easily fixed.

Veneer expands and contracts with moisture. Our veneer is shipped with 7-9% humidity. Keep your veneer stored away from heat sources, and lay it flat.

If your work area is very dry, keep your unused veneer sealed in plastic (a garbage will do) until you are ready to use it.

Q: What species is this maple?

A: Acer Saccharum, or Sugar Maple. Other names are Rock, Hard Rock, and Hard Maple.

Q: What species is this birch?

A: BetulaAlleghaniensis is the name. It can be yellow or white birch, all harvested in North Eastern Canada. The color refers to the bark mainly, as inside the wood is the same color for both yellow and white birch.

Q: How long can I store unused veneer for?

A: Very important to store it laying flat and away from any heat sources. Veneer will absorb and release moisture all the time, so seal the veneer in plastic if the environment is changeable.

Q: What if my veneer splits?

A: Run a bead of glue along the split edges. Use masking tape strips to tightly squeeze the edges together and wait about 2 hours for the glue to dry. Remove the tape before using it.

Q: What is the different between the Face, Core and Cross Band sheets?

A: Face sheets are sorted as the clearest layers for the top and bottom of your project. Core sheets are the internal layers, and will have imperfections such as small knots and holes, splits, sap lines and other color variations. Cross grain sheets (also refered to as xbands, or cross bands) have the grain running in the 90˚ direction to the other long grain layers.

Q: Is this Maple harvested from sustainable sources?

A: The mill we source our maple and birch from complies to and is certified by the Sustainable Forestry Initiative® Program, a worldwide recognized service.

Loading... Please wait...

Loading... Please wait...

USA

USA

Calculated at checkout

Calculated at checkout