- Home

- Skateboard Building

- ProBuilder Kit Longboard

ProBuilder Kit Longboard

Product Description:

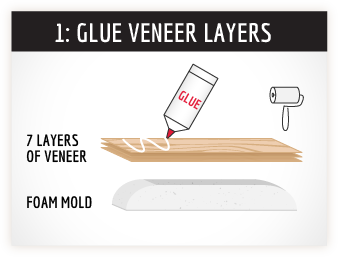

These kits are designed for the board builder who is experienced in the Roarockit vacuum method. Design and shape your own foam mold, press uncut sheets of veneer, then trim and finish your custom design. Instructions do not come with these kits Choose the kit that best suits your needs.

(Wheels and trucks are not included)ProBuilder Kit Longboard contains:

- Two 9-layer sets of maple (and or birch) 12 x 47 x 1/16” veneer

- Each set contains 2 Face, 2 Crossband and 5 Core sheets

- One slab of 12 x 47 x 2” foam for mold shaping

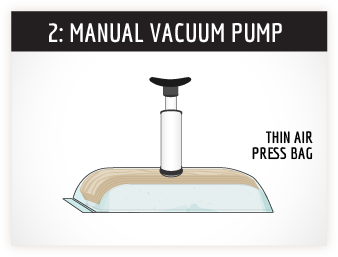

Thin Air Press Kit

- 20 x 70” heavy duty vinyl vacuum bag with one-way valve attached

- manual vacuum Super Pump

- breather netting

- extra sealing tape

ProBuilder Longboard Bag Kit contains:

- A 20x70” Thin Air Press Bag only (no pump, seals or breather)

- Two 9-layer sets of maple (and or birch) 12 x 47 x 1/16” veneer

- Each set contains 2 Face, 2 Crossband and 5 Core sheets

- One slab of 12 x 47 x 2” foam for mold shaping

ProBuilder Veneer Plus contains:

- Two 9-layer sets of maple (and or birch) longboard 12 x 47 x 1/16” veneer

- Each set contains 2 Face, 2 Crossband and 5 Core sheets

- Two slabs of 12 x 47 x 2” foam for mold shaping

Recommended glue amount for these kits: 37 oz

These kits are designed for builders with experience using the Roarockit vacuum-laminating method. Instructions do not come with these kits. For in-depth tutorials view the photo and video tutorials.

Tutorials

Click here to see many related tutorials

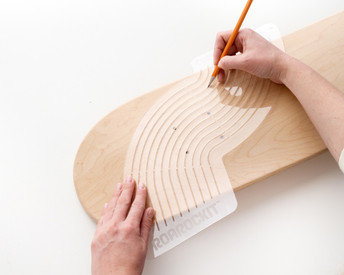

Shaping a Foam Mold

Building a 1” Drop Deck

Watch How to Build a Custom Skateboard Part 1 »

The foam mold, Thin Air Press Bag and pump, edging tool and breather netting are designed to be used for many, many builds.

Keep all your reusable kit parts in good working order by following the maintenance tips included with the kit.

Using uncut sheets of veneer, plywood backer boards and external clamps can puncture a Thin Air Press bag. Treat your TAP bag with care, inspect regularly for holes.

Q: How do I shape the mold foam?

A: View our tutorial first, then assemble the tools to mark, cut and sand the mold foam

Q: What else do I need to make a board with this kit?

A: Glue and a roller, possibly an off-cut sheet of plywood to act as a stiffener under the mold, and a jigsaw (or bandsaw) to trim out the pressed board

Q: How radical a shape will the maple veneers bend around?

A: If you can bend it with your hands, it will bend in the Thin Air Press. Best way to check is to do a DRY RUN, stack your veneer on the mold and press it in the TAP bag.

Loading... Please wait...

Loading... Please wait...

USA

USA

Calculated at checkout

Calculated at checkout