- Home

- Woodworking

- Thin Air Press Bag

Thin Air Press Bag

Product Description:

Get multiple bags for production work, or as a replacement or addition to your other sizes.

Useful for schools and groups and garage builders and woodworkers who require multiple bags so that more than one project can be made during the same gluing session. The kit can be re-used many times, and with a little care and maintenance, can last for hundreds of pressings.

It can be used for any smaller projects, by carefully folding the extra, unused vinyl so that most of the air is removed.

It is important to not have the seams stretched open when it is under vacuum as it will split them apart. See bag project size guidelines below to ensure that there is a recommended 2” wide perimeter of flat vinyl all around the project in the bag.

The Thin Air Press Bag contains:

- a vinyl vacuum bag with a seal and a one-way valve.

- for certain bag sizes, the valve can be positioned in the center (for most wood projects) or off-set for wet resin (epoxy) pressings.

The Elbow Valve contains:

- elbow valve installed on the bag

- (required for use with TUG External Valve Assembly)

Bag Project Size Guidelines:

10.5x40" Bag- Project stack width PLUS thickness must be less than 6.5”

- Project stack length PLUS thickness must be less than 34”

- Project stack width PLUS thickness must be less than 10”

- Project stack length PLUS thickness must be less than 33”

- Due to the rounded end of the bag, if the project width PLUS thickness is less than 6”, project length PLUS thickness can be up to 40”

- The 14x47” bag is intended for use with our preshaped veneer sets, it is NOT COMPATIBLE with Open Source Dancer, Multiboard, or uncut veneer sets

- Project stack width PLUS thickness must be less than 16”

- Project stack length PLUS thickness must be less than 63”

- The 20x70” bag is intended for use with our uncut veneer sets

- Project stack width PLUS thickness must be less than 22”

- Project stack length PLUS thickness must be less than 21”

- Project stack width PLUS thickness must be less than 32”

- Project stack length PLUS thickness must be less than 45”

- Project stack width PLUS thickness must be less than 36”

- Project stack length PLUS thickness must be less than 73”

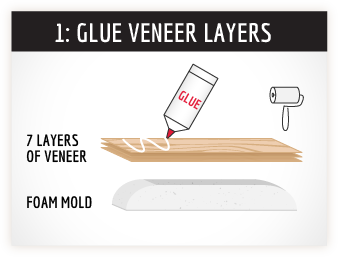

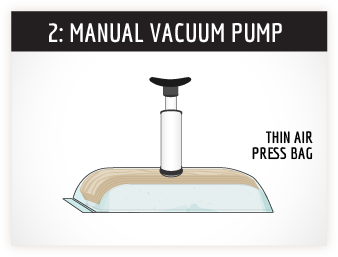

Insert your glued veneers (and mold) into the heavy-duty vinyl vacuum bag, position the breather netting under the valve, seal the bag, connect the Super Pump and extract the air out. Watch as it generates enough pressure to press 7, 8 or even 9 layers of maple into a 3-dimensionally shaped skateboard.

Before you glue up your veneers, a dry run is highly recommended!

Click these links for tutorials on:

Replacing the Sealing Tape Tips Part 1:

Replacing the Sealing Tape Tips Part 2:

Click here for tips on keeping your TAP gear well maintained

Before unrolling, allow vinyl to reach ROOM TEMPERATURE.

Unrolling and using your vacuum bag in cold weather can cause the vinyl to crack.

Tips are included on the maintenance sheet included with the kit.

Keep your TAP bag working efficiently by keeping the sealing tape clean, replacing the paper strip back after each use.

If you suspect leaks in the vinyl, inspect it regularly (see video) and use clear packing tape to stop up any possible leaks.

Ensure your valve has not lifted away from its base, and that the top cap is free of any sawdust, foam bits or glue.

Handle and store your TAP bag so that nothing sharp can puncture it.

Click this link for a tutorial on:

Q: Is this reusable, and for how many times?

A: The kits are designed to be used many many times. With a little care and maintenance, the TAP bags will last for years.

Q: Will the glue stick to the bag?

A: PVA glue and epoxy will not stick to the bag. Any dried glue can be loosened with fingers and either shaken or blown out with a shop vac.

Q: How many projects can I press at once?

A: One piece at a time is recommended. You are limited by how fast your glue dries. If you are using water-based glue, you have about 7 minutes to get the veneer pressed before the glue dries. Dry glue will not bond together.

Q: How can I get the air out faster?

A: These larger bags have a lot of air in them at the start. A quick way to remove the bulk of the air is to remove the top cap of the grey valve, and hover a shop vac hose over the valve. Much of the air can be removed however vacuum cleaners are high volume but low pressure so they will not generate the pressure required to press a deck. Quickly reattach the cap onto the valve and finish the high pressure pumping using the Super Pump.

Q: Why not use an electric pump system?

A: Because this is easier! The TAP valves are designed to work with the manual pumps supplied. The beauty of these one-way valves is that the pump does not need to be hooked up for the entire time the project is drying in the bag. The bag remains air tight, so that you don’t need a constantly running pump. Once a project is pressed, it can be set aside while you go onto other pressings.

Q: If the TAP Bag gets a hole in it, can I fix it?

A: Clear 2” packing tape seals up any suspected punctures. Use a length of the butyl tape to fix any side seam gaps or splits.

Q: Do the valves leak?

A: While many people assume air is leaking back through the valve, they are made of cast rubber and almost never leak. The most common problem with slow leakage is the open-end seal tape. If the seal is not properly closed up (check both sides) you will lose vacuum. If the top cap of the valve is not compromised with dust and debris, the valve will not leak.

Q: Do you refund my veneer if I screw up the pressing?

A: Nope

Q; What’s a “Dry Run” and why should I do that?

A: It means to press your project in the TAP bag, without putting any glue on the veneer sheets. Stack the dry sheets of veneer over the mold, seal them into the press with the breather netting in place, and pump the air out. Check for 10 minutes to make sure the TAP bag is not leaking. This will help you become familiar with the process before you commit glue to your veneer sheets.

Loading... Please wait...

Loading... Please wait...

USA

USA

Calculated at checkout

Calculated at checkout